UKIS New and Used Machinery, Weighing Scales, Parts and Accessories.

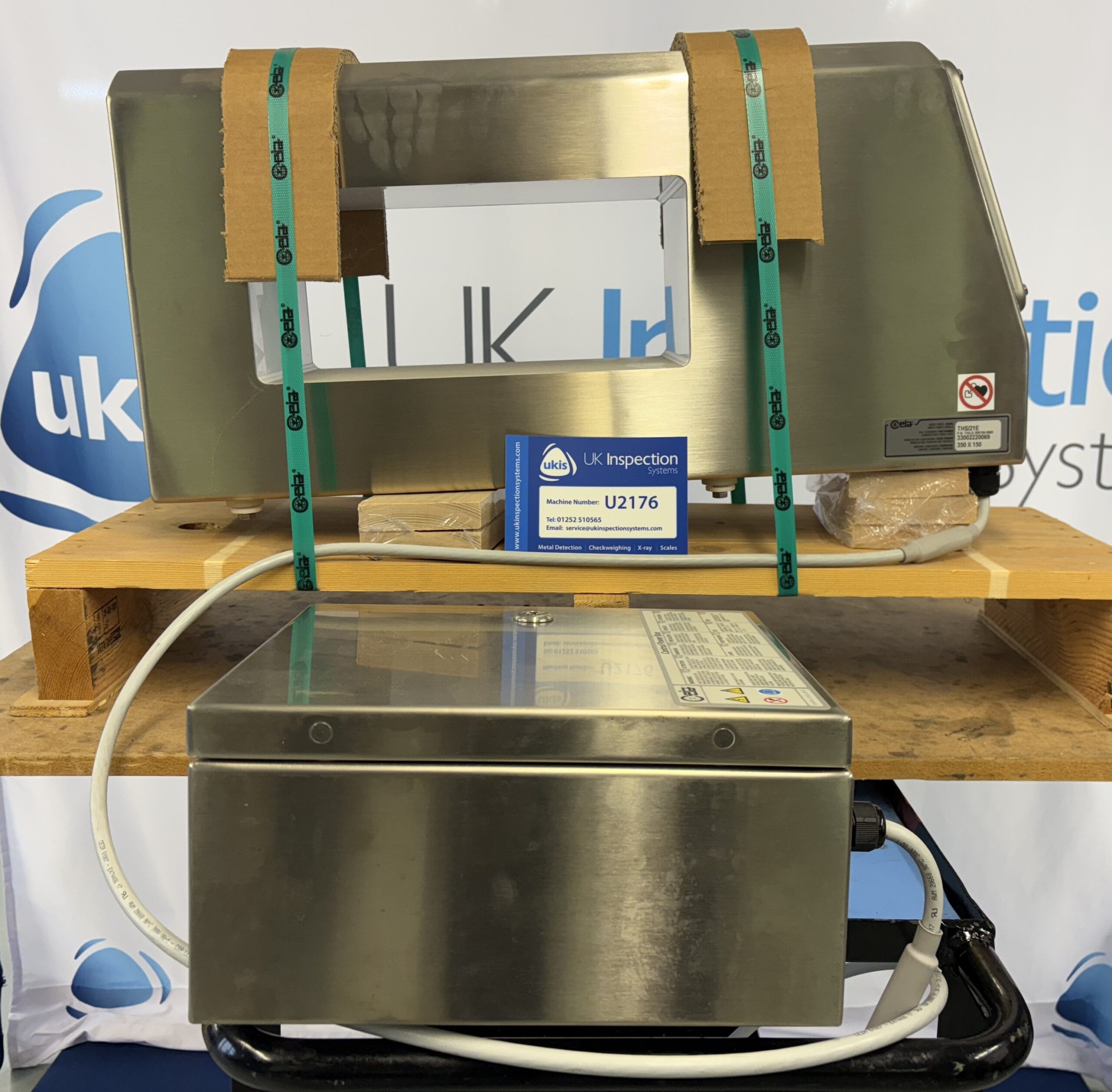

CEIA THS/21E Search Head (NEW) 350 x 150 (U2176)

CEIA THS/21E Search Head offer metal detection, construction quality and reliability characteristics that make them the most suitable and effective solution to automatic elimination of metal contaminants. Fully HACCP and GMP compliant, CEIA Metal Detectors are manufactured according to ISO 9001 certified Quality System using EC and FDA approved materials.

This specific unit is NEW and has a 350mm x 150mm aperture complete with control power box.

Multi-frequency technology (3F version)

The Multi-Frequency Technology allows maximum sensitivity for detection of contaminating metals, both magnetic and non-magnetic and including high-resistivity stainless steels, to be maintained.

An automatic selection function allows the Metal Detector to choose the optimum frequency for the product in transit during the autolearn phase.

The automatic tracking function eliminates any further variations due to the “Product Effect”. The wide pass band of the Metal Detector allows operation at maximum sensitivity at both slow and fast speeds.

The digital analysis of the signal provided by the antenna allows the user to achieve extremely high sensitivity, immunity to interference and operational stability.

CEIA THS/21E Search Head Special features:

- Detection sensitivity: High

- Immunity to environmental interference: High

- Data display type: Alphanumeric OLED - 4x20 characters

- Local programming: 4 keys, 3 with double function

- Control Power Box or Conveyor Control System according to Standards UL 508A and CSA-C22.2 No. 14-05: on request

- Audio and visual detection indicators

- Display of the signal level by means of bar graph

- Inspected/contaminated product counter

- ISO 9001 certified manufacturer

- Extremely compact probe on SL (Slim Line) version

- Detector for magnetic and non-magnetic metals, for use with different types of product thanks to selection of the operating frequency

- Autolearn and automatic tracking of the product effect

- Probe with circular opening for checking material transported in tubing, on THS/G21 series

- Up to 250 product data memories, selectable by local programming or network software

- Up to 40 definable users with username and password

Data management

- Management of electronic production data and electronic signatures as per CFR 21, Part 11

- Data security

- Data integrity

- Data traceability

Events storage

- Complete monitoring of occurred events

- Ejections

- Test results

- Programming accesses

- Programming operations

- Faults

I/O interfaces

- RS232, Auxiliary RS232, BT wireless communication, Ethernet/WiFi/USB (optional)

Signalling

- Acoustic

- Via internal buzzer

- Optical

- Alphanumeric display with bar-graph indication

- Light indicators on control unit: RED: Alarm or Fault / GREEN: Power on

Programming

- Local: built-in keyboard and high-contrast display

- Remote: through computer connected via BT wireless communication, RS232, Ethernet or WiFi and managed with CEIA MD Scope software, THS Production Plus software or any other terminal emulation program or through Web Server (with optional IXC card)

Safety and Security

- Protection degree

- IP65

- On UL versions, the Control Power Box and Conveyor Control System have a 4X-12 certified degree of protection

- Electrical insulation

- Galvanic isolation of the mains voltage

- Compliant with international standards for safety and radio interference

Supply

- Control Power Box

- Main voltage: 100-240 VAC

- Frequency and phase: 50/60 Hz - single phase

- Full load current (FLA): 2.2 A

- Conveyor Control System

- Main voltage: 115 V: 100-120 VAC \ 230 V: 200-240 VAC

- Frequency and phase: 50/60 Hz - single phase

- Full load current (FLA): 115 V version: 11.2 A \ 230 V version: 11.4 A

- Connected motor nominal voltage: 200÷240 V triphase

- Connected motor maximum power: 115 V version: 0.37 kW (0.5 hp) \ 230 V version: 0.75 kW (1 hp)

- Small-size power supply card00211AL_

- Power supply voltage: 20÷30 Vdc o Vac; 2A max.

Environmental conditions

- Temperature

- Operating -10 – +55 °C

- Storage -40 – +70 °C

- Relative humidity Operating / Storage 5 – 90 %, non-condensing

Management software

- THS Production software for statistical and operational management of networked THS systems

- MD-SCOPE for maintenance and programming operations

CONTACT US

Unit 5-6 Elan Court

Norris Way, Rushden

Northamptonshire NN10 6BP

Tel: 03300 888 378

Email: info@ukinspectionsystems.com