Scott Prentice highlights the innovative and clever design helping the ever increasing pressures on food industry inspection applications.

From the birth of concept and following our deep rooted ethos for continued innovative product design and development, flexibility and easy maintenance form part of the key features of our food inspection solutions made in the UK. When it comes to the Aegis Plus Combination System, metal detector and checkweigher, one of those key features that sets it apart is the flexible weighing table length. This system offers a weighing table length that can be adjusted from 350mm to 500mm without extending the overall system length, allowing for minimal change-over time between different product sizes. This flexibility is crucial for companies looking to streamline their production operations and maximize productivity efficiency.

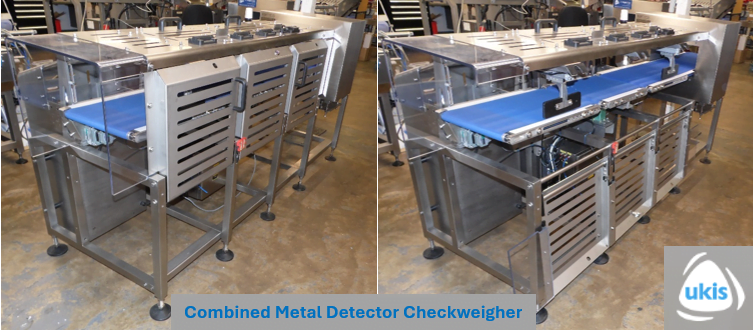

In addition to the versatile weighing table length, the Aegis Plus Combination System also boasts easy maintenance via an access panel, shown above, for easy servicing and hygiene tasks, and a minimal number of quick-release interchangeable parts. This means that maintenance tasks can be completed quickly, at low cost and efficiently, minimizing downtime and ensuring that the system is always running at peak performance. With fewer parts to keep track of, maintenance becomes a much simpler and more manageable process.

The versatility of the flexible weighing table length design on the Aegis Plus Combination System is truly impressive. With the ability to adjust the table length from 350mm to 500mm, this system can accommodate a wide range of product sizes with ease. This means that companies can use the same system for multiple products, reducing the need for separate capital equipment purchase or compensating the upstream or downstream product rate and/or pitching to match fixed specification inline inspection solutions.

Furthermore, respecting that most food production factories are short on space, the design considers and delivers a slimline system width incorporating overhead pushers in opposite to lengthy and protruding pneumatic cylinders without compromising on functionality.

Overall, the time-saving solutions offered by the Aegis Plus Combination System make it a valuable investment for companies looking to optimize their production processes and stay competitive in today’s fast-paced market.

Key to mention is the fact the design does not compromise on the very purpose of meeting regulatory requirements, a top priority for food production companies in the retail industry, and the Aegis Plus Combination System is fully retail compliant. Despite this system offering a flexible weighing table length of 350mm to 500mm, it allows companies to meet and comply with the highest of regulatory requirements for food production.

In addition to its compliance features, the Aegis Plus Combination System also offers a high level of accuracy and precision in weighing and inspection processes. This ensures that companies can meet strict regulatory standards and maintain the trust and confidence of their customers.

In summary, the Aegis Plus Combination System is a flexible and compliant solution for companies looking to meet regulatory requirements and operate with confidence in the retail industry with maximum uptime.

For further product information, please clik here.

Scott Prentice is Engineering Director at UK Inspection Systems Ltd