UKIS New and Used Machinery, Weighing Scales, Parts and Accessories.

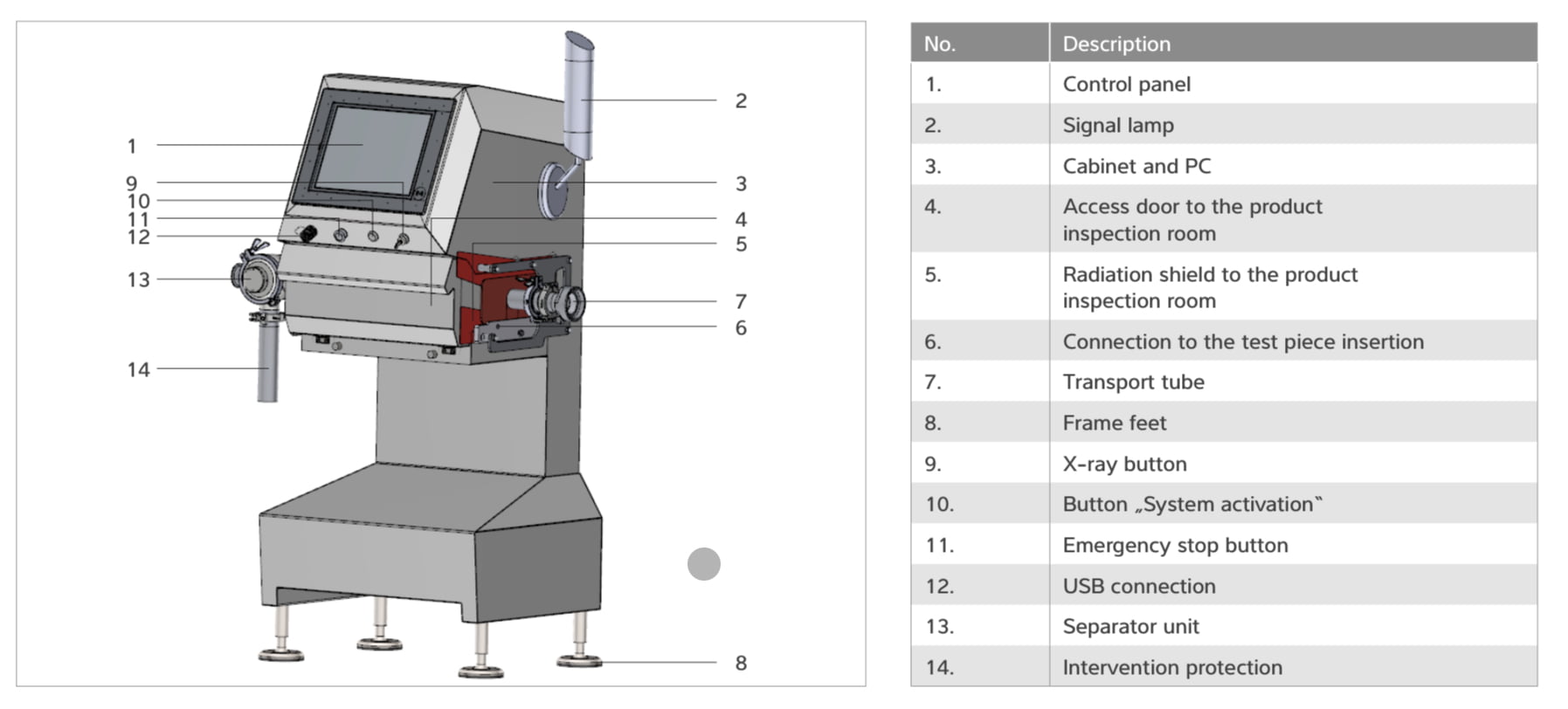

Minebea Dypipe X-ray

Revolutionise your pipeline applications with the cutting-edge X-ray inspection system, Dypipe. Designed to ensure utmost safety and efficiency for pumped paste-like, viscous, or liquid products, Dypipe sets the standard for product integrity and quality control.

Key Advantages:

- Versatile separators cater to diverse product needs.

- Streamlined installation and user-friendly operation.

- Mitigates product recalls, enhancing production line productivity.

- Intuitive interface saves time and minimises errors.

- Seamless integration into existing networks for enhanced connectivity.

- Tailored features for meat processing applications.

Minebea Dypipe Advanced Capabilities:

Detecting metal, stone, plastic, bone, and glass contaminants, Dypipe ensures reliable product quality by excluding imperfect or contaminated items. Its high-pressure system with an easy-open separator is specifically engineered for meat-like products, guaranteeing thorough inspection and compliance.

Minebea Dypipe System Configuration:

Engineered to meet stringent hygiene standards, Dypipe accommodates a wide array of food products including sauces, jams, marmalades, baby food, and minced meat. Its customisable configuration caters to the diverse needs of discerning customers, ensuring optimal performance across various applications.

Elevate your quality control standards with Minebea Dypipe – the ultimate solution for seamless, reliable, and high-performance X-ray inspection in pipeline applications.

Additional information

| Protection class | NW501 – IP65 optional IP69 |

|---|---|

| Nominal width (mm) | 50, 65, 80, 100 |

| Infeed height | 990 mm +/- 100 mm |

| Weight | Approx. 315 kg |

| Throughput capacity Q (m3/h) | NW501 – 3.5 |

| X-ray power | 65 kV 1 mA |

| Detector resolution | 0.8 mm (standard), 0.4 (optional) |

| Approvals | CE |

| Safety locks | SIL 3 Category IV PL e, magnetic |

| User interface | 15-inch touchscreen |

| Operating temperature | +5° to 35°C |

| Machine cooling | Fan |

| Relative air humidity | 20% to 90%, no condensation |

| Digital outputs | 16 available |

| Digital Inputs | 16 available |

| USB port | Yes |

| Network connection | Ethernet |

| Compressed air supply | 5.5 to 6.9 bar |

| Radiation safety | FDA CFR 21 part 1020.40 |

| Electrical supply | 230 VAC ± 10% 50/60 Hz (standard) / 190 to 240 VAC 50/60 Hz (optional) |

CONTACT US

Unit 5-6 Elan Court

Norris Way, Rushden

Northamptonshire NN10 6BP

Tel: 03300 888 378

Email: info@ukinspectionsystems.com