UKIS New and Used Machinery, Weighing Scales, Parts and Accessories.

Dymond X-ray Range

Developed specifically for the food industry, the Dymond X-ray raises the bar in X-ray inspection technology. Delivering high sensitivity with low power consumption the unit provides unparalleled accuracy and reliability. The user interface is icon-based which means that products can easily be set up or adjusted by line operators without special training or previous X-ray knowledge and without the involvement of an engineer. Available in a range of sizes for different applications.

Dymond – Inline inspection and integration into your networks

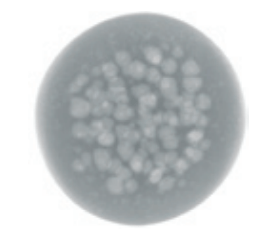

All of the Dymond series X-ray inspection devices guarantee reliable vertical inspection. Foreign objects made from metal, glass, stone, bone and various plastics are detected inside food packaging and eliminated from the production line. A broad range of standard functions also ensure product integrity and quality, for example through

- completeness checks

- product weighing

- determining weight of individual areas

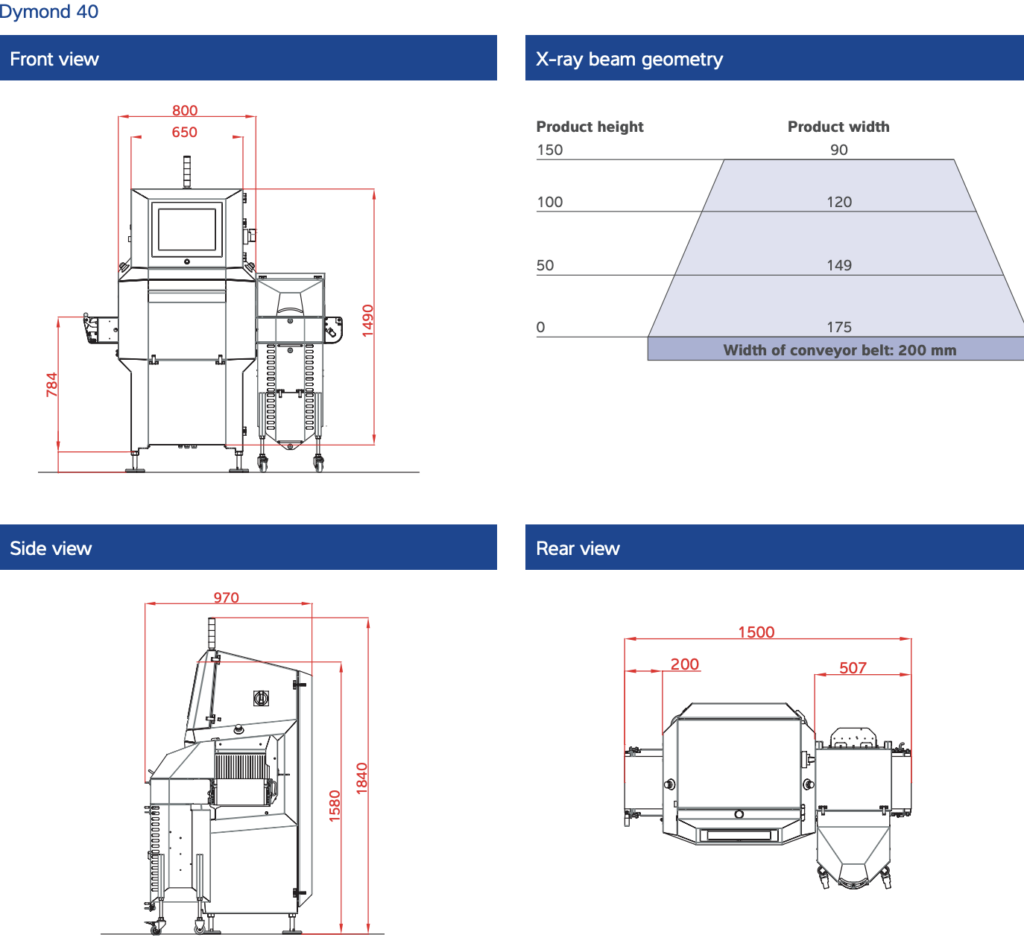

Specification:

- Control: 15″ colour touchscreen interface – all models

- Belt speed: 10 to 49 m/min (standard) | Up to 73 m/min (optional) – all models

- Conveyor height: 800 – 999mm – all models

- Radiation safety: FDA CFR 21 part 1020,40 – all models

- X-ray power: Dymond 40 & 80: 70 kV; 1.4 mA Dymond 120: 80 kV; 2mA Dymond 160: 90 kV; 3.5 mA

Features:

- High detection sensitivity

- Simple maintenance and cleaning

- Ensures product safety with virtual testing and parallel image processing

- Meets and surpasses a comprehensive range of environmental and hygiene regulations

- Outstanding detection performance while ensuring maximum line speeds

- Multi-lane solutions for up to eight lines through one detector

- Integrated network compatibility, allowing remote access by for quick fault diagnosis and support

CONTACT US

Unit 5-6 Elan Court

Norris Way, Rushden

Northamptonshire NN10 6BP

Tel: 03300 888 378

Email: info@ukinspectionsystems.com